I posted the gist of this in another thread but I am hoping that making a dedicated thread on this topic results in some CONSTRUCTIVE conversation regarding N5x oiling. Are there improvements that can be made other than just blaming oil? Or, are all the street racing bros right that Rotella is life? I think there is more to discuss here, myself...

I recently wiped my rod bearings on track at 115k miles

The above is a short rendering of lap #2 which was the only complete lap I got in for the second session of the day before the car rolled to a stop. Oil peaked 26xf and coolant peaked 220f on the straight. 3 turns later and it just died.

I decided to rebuild the engine myself. this gave me a first-hand look at what went wrong. Here is an album of all the pics I took during this process:

https://drive.google.com/open?id=1CtV8pJYwjm-R2lBLrVuWmWSCevqbfJtD . I was a bit too busy with the build itself to worry about documenting key processes, but I can answer to the best of my ability any questions you may have. I was also a bit busy sorting out ECS Tuning's part # mistakes... Those guys really do just blindly throw crap in a box and ship it out.

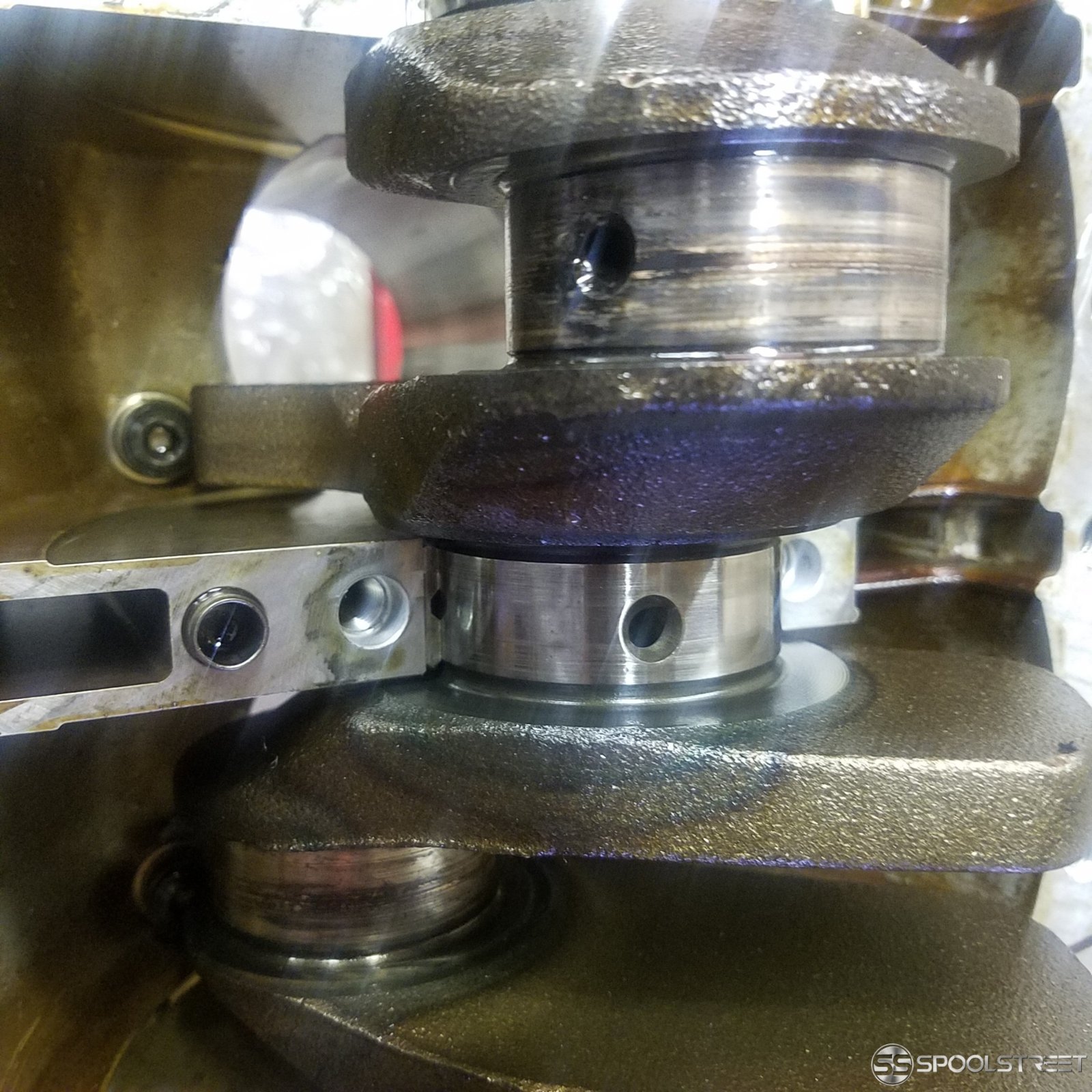

From what I can tell, it looks like the oil pickup ran dry. The rod bearings literally melted themselves to the crank. The crank journals were not actually all that bad once the babbit material was peeled off. However, the crank took a ton of heat and so did the rods. I was lucky nothing let loose. Rod/journal #1 was the only one that looks like it got a bit of oil and fared a bit better than the rest.

Some notes from the tear-down: intake and exhaust cam ledges looked perfect still. The bottom end was burnt to a crisp. The cylinder walls, valves, pistons, and the main bearings looked OK with the exception of 115K miles of wear and tear. The cylinder head was pretty clean with no sludge (5-6k oil changes with Castrol Edge 0-40 EU). I have done multiple Blackstone analysis in the past and there was never any indication of an issue. In fact, they kept telling me to run my oil longer (7k+ miles). So, lets not go down that road of fuel dilution, thin oil, etc. Oh and yes, 7qts of oil drained out of the pan. In fact, it was about 1/2qt over-filled when this happened. I had just changed the oil the previous weekend and threw in the extra 1/2qt right before the event.

N54 and N55 failures seem to happen pretty frequently at the track. Sometimes there is so much heat generated that the engine throws a rod. In my opinion, the oil pan is pretty poor design for performance work. While the N55 did get a revised windage tray and oil pickup tube, over the outgoing N54, the pan itself is virtually the same for manual cars. The engine sits at an angle and the oil pan sits parallel to the ground. This results in a sump area that has a triangular shape/slant as one edge has to taper to meet the block. The horizontally cut and narrower pickup tube on the N55 seems to be an improvement over the N54 pickup tube for ensuring suction. However, neither pan has a baffle or any kind of provisions for ensuring the pickup stays wet. BMW points this out themselves on page 57 of the "S55 engine PDF." I can see how a situation like being 1/2-1qt low on oil and doing some high rpm pulls and then hard braking could easily run the pickup dry causing bearing wear. Or, if you're coming off a banked straight-away in 5th gear and toss your car into a few steady state turns...

To add to this, people seem to have really bought into the misnomer that N55 is "more reliable" than the N54 (yes the turbos and injectors might be but the bottom end has the same integrity) that they are buying N55's for track duty and thrashing them. It's not going to end well if you think a luxury commuter car can be "raced" on slicks without dropping some money into it. No, 60wt race oil isn't going to help you either. People love to say "LS swap it" but if you dig you'll find that just as many LS motors have had issues with oil starvation at the strip and track. I am not talking about the occasional beginner HPDE. If you want to get serious with the car, you'll need to get serious about oiling.

At autocross, I've logged ~10psi oil pressure under heavy braking. I never really thought much of it since "everybody does it so how can it hurt?" Well... 115K miles later, multiple HPDE days with rcomps, and 20+ autocross events and I am writing this post. I can't blame ll-01 oil, I can't blame dirty oil, and I can't blame "N55 intake camshaft oiling issues." I can only blame myself for ignoring what was a pretty transparent problem. It's even more funny to me now after tearing down the engine and seeing this issue first-hand and then seeing all the M235i owners at the track saying they bought their cars because they are more reliable than E-series N55. "Well BMW races the 235i." NOPE. Only the M235iR got the M2 oil pan...

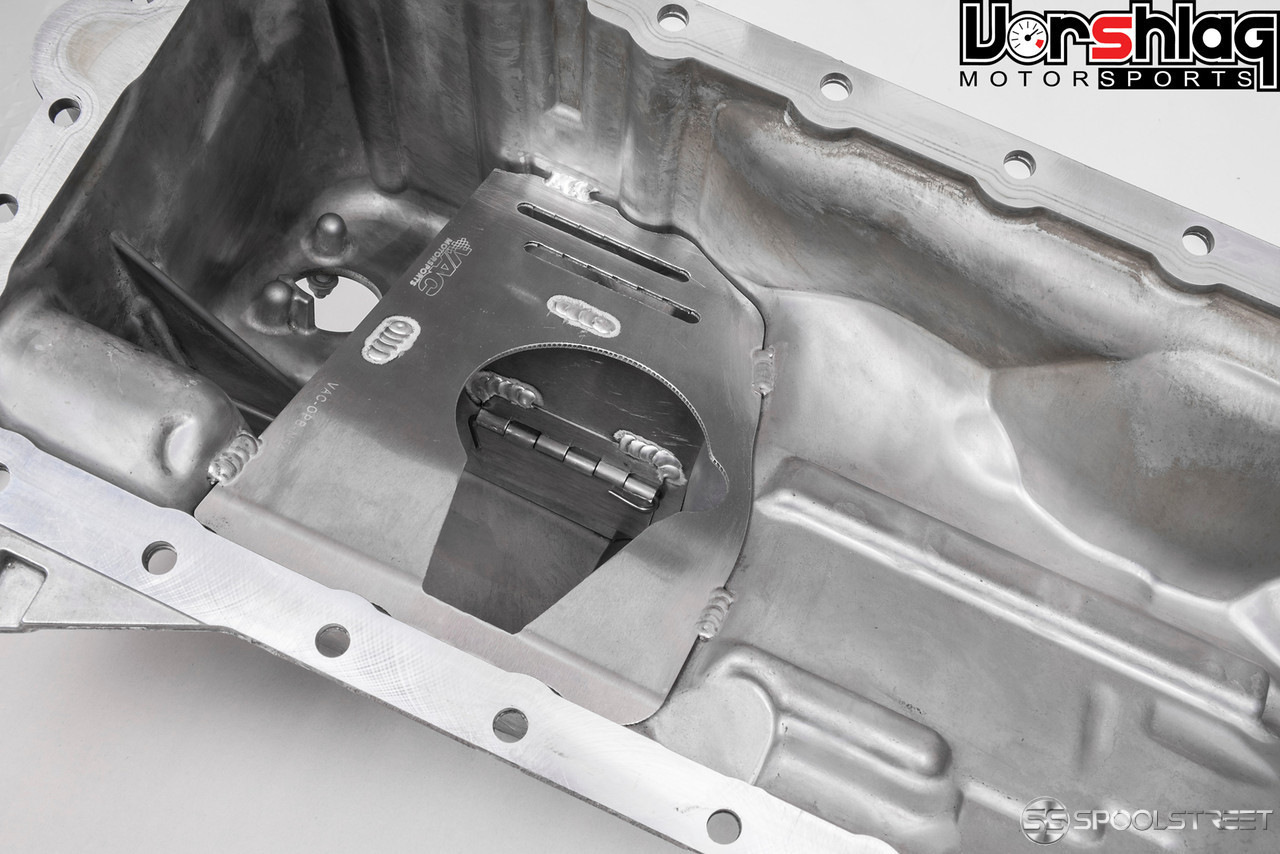

Here is the M2 pan design (shares the same oiling system with the M3 and M4):

Not only is there a baffle to keep oil from sloshing away from the pickup, there is also a secondary pump which sucks oil from the front of the pan[and turbo drains] and dumps it to the rear (semi-dry system). Even this system is only rated for 1.2g of sustained g-force, per BMW. If only it weren't so expensive of an option... I'd definitely look into retrofitting this setup.

My current solution:

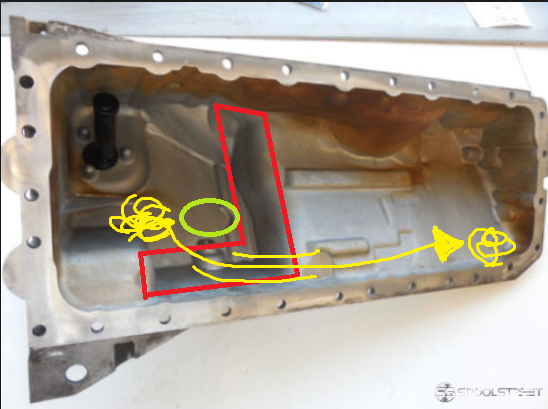

I took some aluminum sheets and welded a ~1-1.5" wide "L-shaped" piece into the corner of the oil pan surrounding the pick-up tube. I didn't take pictures, unfortunately. I chose this L-shape as it mimics to a lesser extent what BMW did with the M2 oil pan. This is also similar to GM's "batwing" oil pan in the LS swap world.

Before anyone mentions it, I did not like the look of the VAC oil pan baffle. It looks like it would reduce the pick-up area to half of the sump and restrict the return of oil to the pickup in some situations. Turner has made baffles for previous generations, like the s52, which make more sense than this piece, imo.

A baffle alone is not going to cure this problem. It seems obvious that if you need an enclosure like VAC's to keep oil around the pickup that oil is not going to be returning to that trap fast enough either. Meaning, that ~1qt you managed to trap MIGHT last 1 full second before running dry itself... our cars can easily pump 3qts of oil out of the pan in a 2 second long sweeping turn or a 2 second long threshold braking situation like at the end of a drag run. On to the second solution:

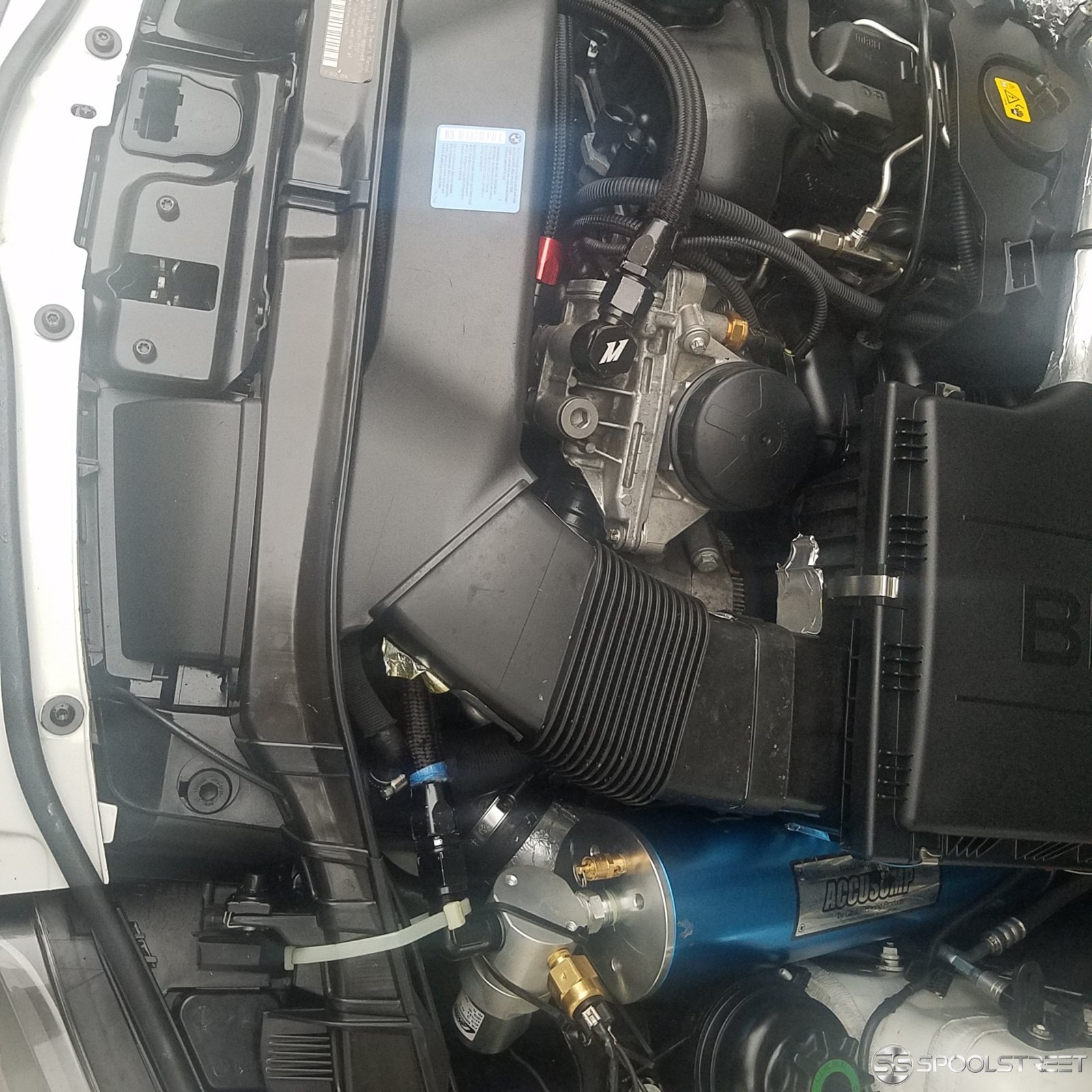

- A 3qt oil accumulator (Accusump)

While an oil pan baffle helps ensure oil doesn't slosh away from the pick-up tube, there are still going to be oiling issues in long sweeping turns. Hence, why BMW put a second pump in the front of the M2 pan. This is where I hope the Accsump will help.

The Accusump is plumbed into the oil return side of the thermostat housing and operated off an electronic valve. In the event that the pickup tube does run dry, the 55psi electronic valve on the Accusump will open at <55psi and allow the accumulated oil to be released. I went with the 55psi valve because the 35psi option just seems like too little too late given that our cars run at significantly higher pressure then that at all times. 35psi might make more sense for a typical car that sees 15psi at idle and 60psi under load. Oil pressure on our cars rises to around 80psi under load.

The electronic valve is always allowing oil to enter the accumulator so oil capacity and pressure inside the accumulator will naturally equalize to the PEAK operating pressure of the vehicle. I have seen the Accusumps accumulated oil pressure sitting at 110psi due to cold starts. This pressure is only allowed to RELEASE when the electronic valve is given the 12v signal from the pressure solenoid (pressure dropped below 55psi). Of course, the pressure bleeds off quickly when the Accusump starts to dumps but it takes several seconds for it to empty and drop below ~40psi. I will try to log the oil dumping to show how long it takes to empty when the car is off.

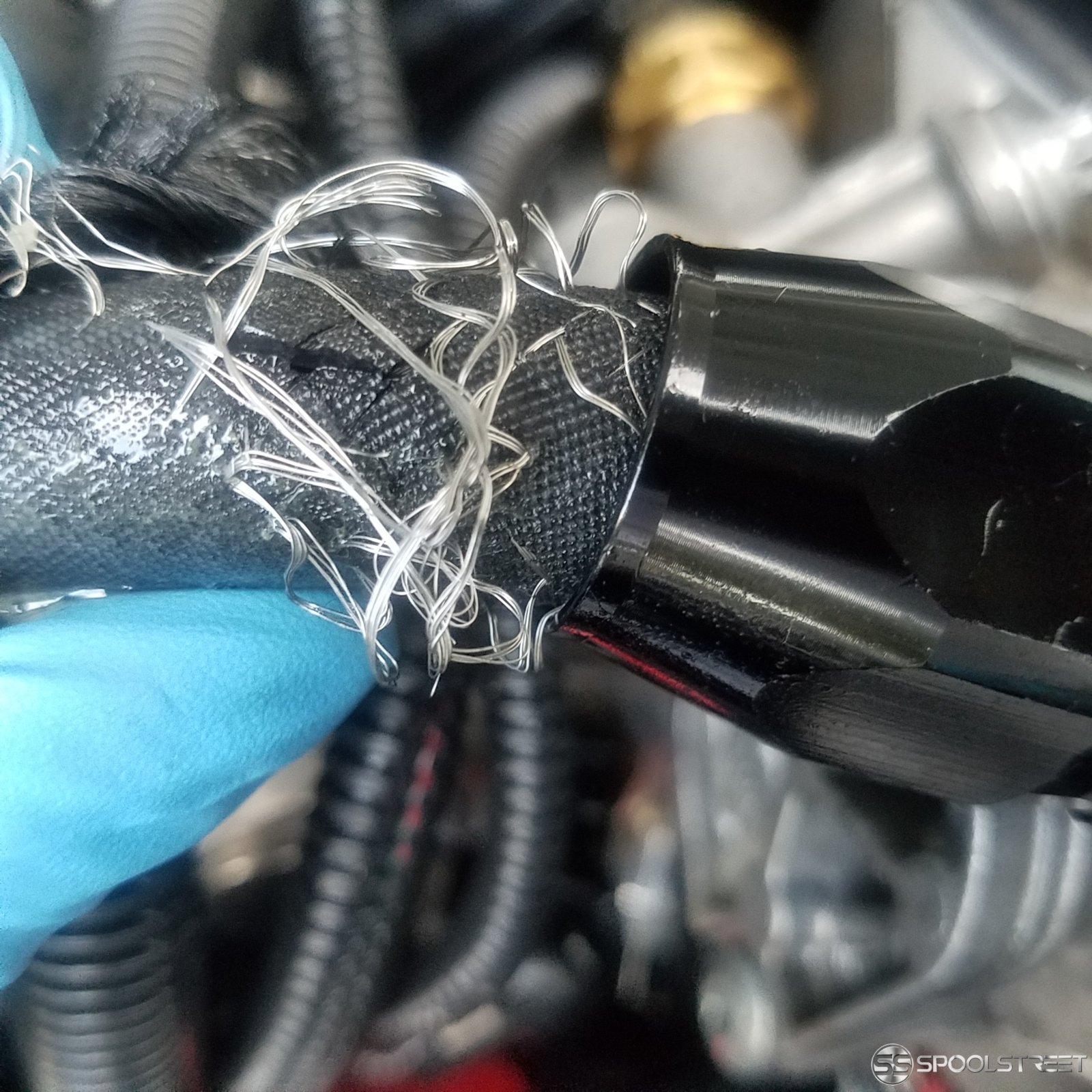

PSA: don't buy $2/ft nylon braided AN hose off EBAY lol You will be cleaning up oil for weeks when a defect in the line causes it to burst spraying oil EVERYWHERE. And, this lead to tons of other problems like killing my brand new tensioner, pulley, and belt. Don't be cheap and try to get away without replacing your belt after oil gets on it either. Mine shredded a week later and I ended up having to then re-do the brand new front crank seal and drop the oil pan. Nightmare.

I can quote use cases all day to support the effectiveness of the Accusump (lotus uses them), but, I am a skeptic and seeing is believing. Most of the negative things I have seen are user error (like killing the solenoid by allowing it fire 24/7 to dump oil at idle). Maybe I'll eventually buy an electronic pressure gauge so that I can log the Accusump activity. For now, I wired up a simple 12v light into my dash to illuminate when the Accusump activates.

Another benefit of the Accusump is that it can be used to prime the engine prior to starting. It can build 40psi oil pressure even before cranking on a cold start.

https://datazap.me/u/banks334/accus...tart?log=0&data=4-13-16&solo=13&mark=62-32-86

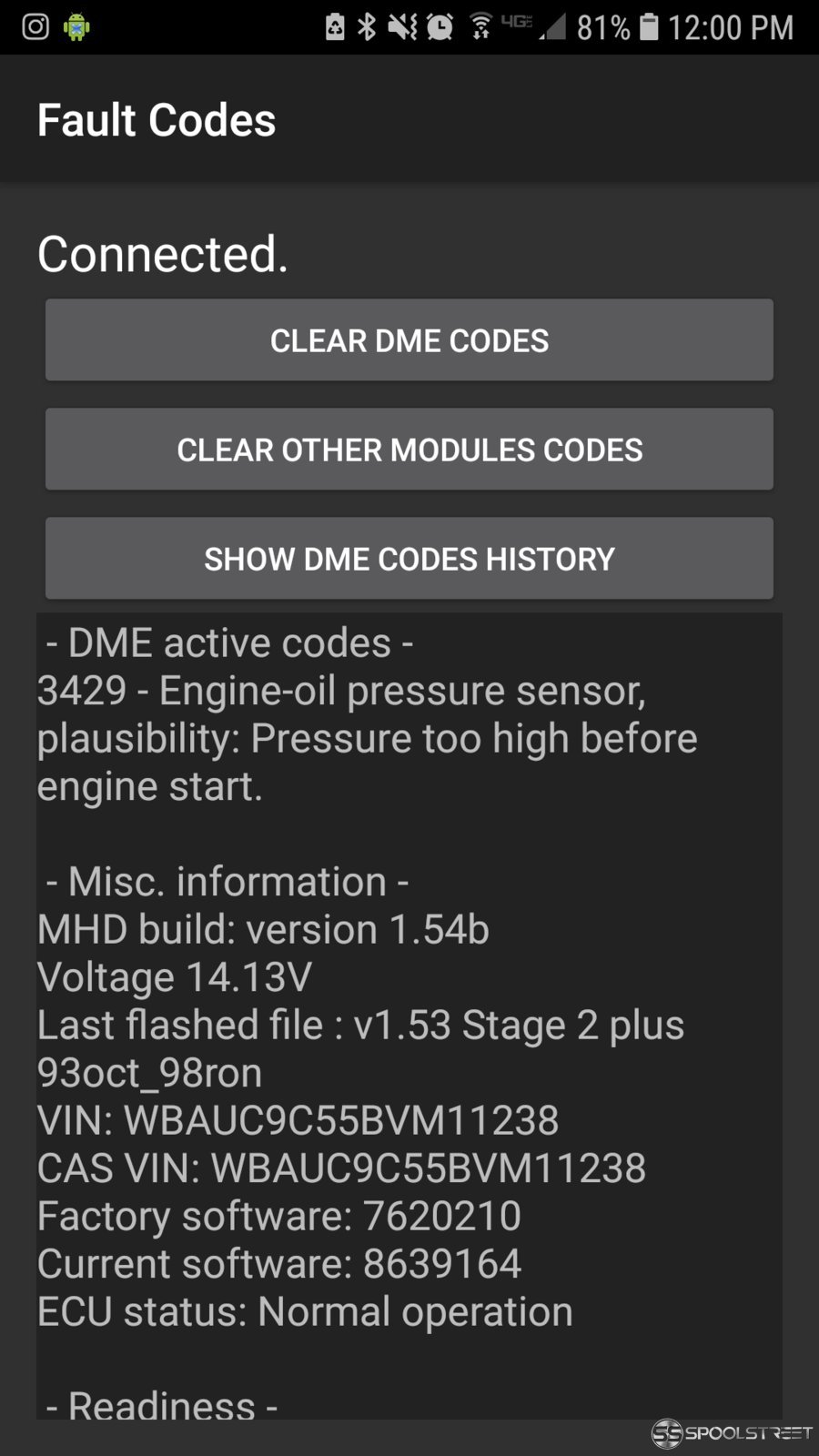

The only drawback? I've hit a DME safety roadblock. The DME is seeing the higher then expected oil pressure prior to starting and throws a CEL. The oil pressure relief valve is then put into a fail-safe mode and the oil pump delivers 100% of its volume to engine (N55 has electronically controlled oil pressure). I don't think it's OK though to daily drive with 110psi oil pressure. This is something I ask the community to help figure out in order to make this feature of the Accusump usable.

Anyone else have thoughts or theories? Any actual "race" teams or engine builders have experience to share? Perhaps the tight bearing clearance results in high bearing temps? Babbit failure due to heat and/or compounding wear from intermittent oiling starvation issues? As seen in the pics above, my bearings literally melted to the crank. I know we've seen all sorts of theories out of the M motor spun bearing issues ranging from oil weight to rod bearing clearances. I've also seen also sorts of speculation about positive displacement oil pumps causing cavitation issues. I don't believe too much in this since the oil pressure sensor would see that type of loss of pressure... it would show in a log. I do think that there is some weight to the rod bearing clearances. I did not measure stock clearance since only rod #1 was measurable, but I did measure during assembly and I landed at right around ~.016" on all rods and mains. Some clearances were a hair wider or tighter. That is pretty tight for 40wt oil spec and close to a 2" diameter crank. KING specs .020"-.025" clearance for "performance" builds. I have also read that tighter than normal tolerances are perfectly fine on an aluminum block. It's hard to separate the facts from the fiction. Lot's of information is just regurgitated from decades old old-school knowledge.

Update:

Here is some autocross comparison data:

https://datazap.me/u/banks334/autocross-accusump

View attachment 25970

There are 3 logs there, the first log is with the Accusump, the second log is without the Accusump, and the third log is of oil pressure on decel in order to be able to compare actual oil pressure during the runs to what oil pressure is supposed to be.

You can see that oil pressure is dipping down to ~40psi during several turns and rpm is still above 3,000rpms which means oil pressure should be over 60psi. This could potentially indicate that the pick-up is grabbing some air. With the Accusump (60psi electronic valve), oil pressure is above 60psi across the run except in two places toward the end. Oil pressure dips in two places down to about 48psi. The short bursts of acceleration in an autocross probably limits how well the Accusump can re-fill. The results are still much better than the run without the Accusump.