You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It should hold oil at the pick up better under higher G - forces vs. stock. But the oil it does accumulate there will be consumed rapidly and the same issue of oil starvation will likely come back in sustained high G force corners, since the normal N55 doesn't have the secondary oil pump to dump oil back into the pick up area.nice. Would be interesting to hear from the guys in this thread that have mounted their own baffles and if they think this design would work better than what they have implemented.

VAC just released their baffle.. maybe a bit too late? idk

https://store.vacmotorsports.com/vac-motorsports-oil-pan-baffle-bmw-n55-p4854.aspx

View attachment 34634

View attachment 34635

The fact that they don't offer logs to support their claims, and mention acceleration loads rather than braking loads (which is the actual problem) tells me that they didn't test their product and don't know if it actually works.

I have reached out to them.

I may have discussed with a few of you on. Facebook.

At a recent trackday at Silverstone GP circuit I was able to log oil pressure and found only drops under very hard braking.

Lowest was 25psi.

I have done 14 trackdays and had no engine problems yet. (I run 5w40 millers cfs nt+ and 1.5L overfill with a csf oil cooler).

I have M135i f21 to be clear.

Keeping the rpm up did help this. I guess pumping ratio etc.

As it was under no load I don't see it being too much of a problem.

If VAC don't come back to me with data etc then I will proceed with my custom baffle installation.

From what I understand the oil pans betweem n54 and n55 are basically the same and that some people seem to think the VAC baffle doesn't seem to do that much.

And also as some others have said it looks like it can restrict oil flow in some cases

I still think many seizures can be attributed to overheating / thin oil. Stock oil cooler can't cope and with 115c cruising temperature it will bet to 140c in a matter of a few laps. I believe that's what happened with the f30 chap unfortunately.

I may have discussed with a few of you on. Facebook.

At a recent trackday at Silverstone GP circuit I was able to log oil pressure and found only drops under very hard braking.

Lowest was 25psi.

I have done 14 trackdays and had no engine problems yet. (I run 5w40 millers cfs nt+ and 1.5L overfill with a csf oil cooler).

I have M135i f21 to be clear.

Keeping the rpm up did help this. I guess pumping ratio etc.

As it was under no load I don't see it being too much of a problem.

If VAC don't come back to me with data etc then I will proceed with my custom baffle installation.

From what I understand the oil pans betweem n54 and n55 are basically the same and that some people seem to think the VAC baffle doesn't seem to do that much.

And also as some others have said it looks like it can restrict oil flow in some cases

I still think many seizures can be attributed to overheating / thin oil. Stock oil cooler can't cope and with 115c cruising temperature it will bet to 140c in a matter of a few laps. I believe that's what happened with the f30 chap unfortunately.

Last edited:

I have reached out to them.

I may have discussed with a few of you on. Facebook.

At a recent trackday at Silverstone GP circuit I was able to log oil pressure and found only drops under very hard braking.

Lowest was 25psi.

I have done 14 trackdays and had no engine problems yet. (I run 5w40 millers cfs nt+ and 1.5L overfill with a csf oil cooler).

I have M135i f21 to be clear.

Keeping the rpm up did help this. I guess pumping ratio etc.

As it was under no load I don't see it being too much of a problem.

If VAC don't come back to me with data etc then I will proceed with my custom baffle installation.

From what I understand the oil pans betweem n54 and n55 are basically the same and that some people seem to think the VAC baffle doesn't seem to do that much.

And also as some others have said it looks like it can restrict oil flow in some cases

I still think many seizures can be attributed to overheating / thin oil. Stock oil cooler can't cope and with 115c cruising temperature it will bet to 140c in a matter of a few laps. I believe that's what happened with the f30 chap unfortunately.

Would love to see the track log you mentioned!

I guess silverstone GP isn't too challenging for our cars in terms of keeping oil pressure up. Ut is a right hand circuit with no left hand hairpins if Im correct? What I have seen with both the M135i and my own car is that you need the combination of trail braking and a sharp left hander to see the drop in turns.

As for the baffle, we do not actually have any before and after data. But since my baffled sump copes better with braking than my friends non-baffled car, it is tempting to assume that my baffle helps a little during braking.

Anyhow, as of now, the only solution we know works for sure is the accusump. My next attempt will be to deepen the sump and add a dip stick, but I won't be able to do that until China returns to normal. Heck, I haven't even checked if there is enough room for such a mod yet.

So I believe that is what we know so far.

Last edited:

I still think many seizures can be attributed to overheating / thin oil. Stock oil cooler can't cope and with 115c cruising temperature it will bet to 140c in a matter of a few laps. I believe that's what happened with the f30 chap unfortunately.

From what I understand, modern synthetics don't drop off aggressively in viscosity as they heat up like people always claim. A good synthetic, like LL-01 oils, are good for 300f+. Oils are torture tested at 300f (ASTM D4683, D4741, or D5481) giving them their HTHS rating. Just looking at random viscosity vs temperature charts on google, a 5w-40 oil will have a kinematic viscosity of about 12-15cSt at 100c and that "thins out" at 150c (302f) to about 10cSt. Not much. Hence why BMW doesn't start engine power reduction until 300f+ and doesn't throw limp mode until 315f?+. Not sure of the exact numbers... just going off the top of my head. Oil intervals are obviously dropped drastically.

I personally feel like oil isn't as much of an issue as everyone immediately points to when stuff like this happens. "OP probably just never changed their oil." "They must have been following BMW's 15,000 miles oil changes." Nah... MAYBE heat and swelling of the crank/rod bore choking off oiling clearances would be something to look at (bolt a rod to a crankshaft and check clearance after baking at 350f?), but, that's not an issue with the oil itself. Unless of course you're running too thick an oil that is causing temperature to rise unnecessarily or something...

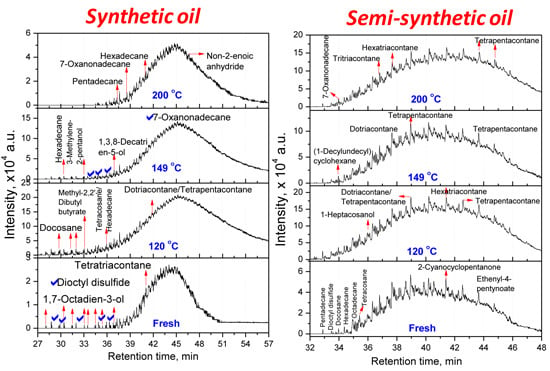

There are a LOT of technical articles out there if you can navigate through the jargon. Also ignore anything older than 20yrs or so as technology has changed oils rapidly... attached is a picture of synthetic oil maintaining it's weight up to 240c or so (464f) at which point it starts flashing off (boiling) rapidly. And then another chart showing aging of oil at various temperatures and measuring the impact on the oils density (of which kinematic viscosity is a derivative of). "The kinematic viscosities of synthetic and semi-synthetic oils decreased by 4% and 8.2%, respectively, at 149 °C. This is expected because high decomposition temperatures tend to break the hydrocarbons present in oil by the attack of oxygen via alkoxy and peroxy bond β-scission, which leads to a decrease in dynamic viscosity. " This was after 120 hours... 4% viscosity loss at 300f. Not sure if this was performed under load or not though.

Characterization of Thermal Stability of Synthetic and Semi-Synthetic Engine Oils

Engine oils undergo oxidative degradation and wears out during service. Hence it is important to characterize ageing of engine oils at different simulated conditions to evaluate the performance of existing oils and also design new formulations. This work focuses on characterizing the...

Attachments

Last edited:

Would love to see the track log you mentioned!

I guess silverstone GP isn't too challenging for our cars in terms of keeping oil pressure up. Ut is a right hand circuit with no left hand hairpins if Im correct? What I have seen with both the M135i and my own car is that you need the combination of trail braking and a sharp left hander to see the drop in turns.

As for the baffle, we do not actually have any before and after data. But since my baffled sump copes better with braking than my friends non-baffled car, it is tempting to assume that my baffle helps a little during braking.

View attachment 34900

Anyhow, as of now, the only solution we know works for sure is the accusump. My next attempt will be to deepen the sump and add a dip stick, but I won't be able to do that until China returns to normal. Heck, I haven't even checked if there is enough room for such a mod yet.

So I believe that is what we know so far.

Unfortunately it was my first time using the MHD and assumed that the automatic logging always logged like torquePRO did.

VAC have yet to reply to my Email or FB message

There is a hard braking into hard left corner at the GP circuit. This is where I dropped oil pressure to 25 on one occasion.

Your sump baffle is interesting - looks good. Do you literally have the surround as pictured? Do you have any trap door or one way valves? I notice something on the back side...

It looks effectively like you have a plate around the pick up and a flat plate going down.

I was thinking of doing something similar, just with some holes on the back side to allow oil though. Although, I will do some testing with water to simulate oil flow etc before making the final install.

I will not be running a return through a cooler like you though...

@Bnks - as I am on a mobile right now it's hard to answer all of your points.

But a normal Castrol "synthetic" (which is not a proper true synthetic) at 30w may not cope with extremes of track use for long periods. Not only the oil temperature but the surface temperature of mating surfaces and bearings etc.. simply something it's not designed for.

The measured oil temperature is not the temperature of the oil at the rod bearings for example. It would be quite a bit hotter!

The UK cars I know that have seized (only 2 or 3) have all had proper abuse - long stints on track, extended dougnuts etc. All of these cars reportedly used the required 5w30 Castrol LL01 oil.

A 5w30 at 100c let's say an example oil cSt is 10.5.

The same brand of oil but in 5w40 at 100c is 13.8 cSt.

Of course these cars already run hot (I suspect for emissions/economy). These are the factory numbers for fresh oil too - not 10k old oil.

So at 140c you can maybe see the difference is even more...

Which is why I use a Ester based competition oil from Millers. Reasonable use - short-ish stints on track, etc so far I have had no issues.

Not a guaranteed thing. But every little helps. Maybe it is just a small safety net.

Happy driving

So at 140c you can maybe see the difference is even more...

Which is why I use a Ester based competition oil from Millers. Reasonable use - short-ish stints on track, etc so far I have had no issues.

Not a guaranteed thing. But every little helps. Maybe it is just a small safety net.

Happy driving

Yeah I understand the concern of high temperature but I literally just linked you to a scientific paper that shows even a semi-synthetic oil doesn't lose as much kinematic viscosity as you're claiming... You're proving my point about oil myths I think. Worst case scenario a 10.9 cSt 30 weight oil would still have a cSt rating of over 10.0 at 300f. That loss is actually seen over hours of service too as the oil ages not just instantly on fresh oil.

Kinematic viscosity (measured as cSt) is a really meaningless value in the context of bearing lubrication and film thickness in high temp high shear scenarios. It's really only relevant for pumping losses. A counter-intuitive example I like to give is how 0-30 Castrol edge EU has the same HTHS rating as 0-40 Castrol edge EU despite the 0-40 having a higher kinematic viscosity. Ll01 oil will all be above a HTHS value of 3.5cP which is why I mentioned the LL-01 standard. Whether you buy a 5w-40 with a HTHS of 3.6cP-3.7cP or a 5w-30 oil with a HTHS rating of 3.5cP isn't going to make a damn lick of difference. It's an extremely marginal difference. But yes absolutely, a high quality oil will likely perform even better than the already really high standard of BMW's LL-01.

Overall point being, those people were going to spin bearing regardless of what oil they put in the car. Unless it had hundreds of hours of run time on it and was fuel diluted or something. More important than the oil they were running I think would be the activities they were doing "donuts in a parking lot." aka aerating the oil (whipping it up into a foam) and possibly exposing the pickup intermittently.

Hey I could be dead wrong about oil and that is OK too lol but where you're seeing an oil trend I am just as easily seeing an "activities" trend.

Here is an M3 going pop after some donuts... for your entertainment... Highly doubt it blew up because of the oil he was running or how hot the oil was. You'll find a lot of threads on the Subaru forums about people blowing engines after doing donuts if you want to see more carnage lol.

Last edited:

Unfortunately it was my first time using the MHD and assumed that the automatic logging always logged like torquePRO did.

VAC have yet to reply to my Email or FB message

There is a hard braking into hard left corner at the GP circuit. This is where I dropped oil pressure to 25 on one occasion.

Your sump baffle is interesting - looks good. Do you literally have the surround as pictured? Do you have any trap door or one way valves? I notice something on the back side...

It looks effectively like you have a plate around the pick up and a flat plate going down.

I was thinking of doing something similar, just with some holes on the back side to allow oil though. Although, I will do some testing with water to simulate oil flow etc before making the final install.

I will not be running a return through a cooler like you though...

@Bnks - as I am on a mobile right now it's hard to answer all of your points.

But a normal Castrol "synthetic" (which is not a proper true synthetic) at 30w may not cope with extremes of track use for long periods. Not only the oil temperature but the surface temperature of mating surfaces and bearings etc.. simply something it's not designed for.

The measured oil temperature is not the temperature of the oil at the rod bearings for example. It would be quite a bit hotter!

The UK cars I know that have seized (only 2 or 3) have all had proper abuse - long stints on track, extended dougnuts etc. All of these cars reportedly used the required 5w30 Castrol LL01 oil.

A 5w30 at 100c let's say an example oil cSt is 10.5.

The same brand of oil but in 5w40 at 100c is 13.8 cSt.

Of course these cars already run hot (I suspect for emissions/economy). These are the factory numbers for fresh oil too - not 10k old oil.

So at 140c you can maybe see the difference is even more...

Which is why I use a Ester based competition oil from Millers. Reasonable use - short-ish stints on track, etc so far I have had no issues.

Not a guaranteed thing. But every little helps. Maybe it is just a small safety net.

Happy driving

Yes there is one trap door down there that you can almost see.

IDk what tables were modified, or if it helps anything, but Twisted Tuning has me at about 10psi higher than stock on my N55.

Im interested in taking a look at the region where coolant temp influence oil pressure targets off a cold start. Seems like on a cold start oil pressure drops to 40psi at around 110f or so. Oil is still pretty thick at that temperature and before this changeover is reached im usually still idling at 80psi+. I'd like to see that threshold changed to like 140f+ before dropping pressure target to basically what it is during a hot idle.

Last edited:

IDk what tables were modified, or if it helps anything, but Twisted Tuning has me at about 10psi higher than stock on my N55.

Im interested in taking a look at the region where coolant temp influence oil pressure targets off a cold start. Seems like on a cold start oil pressure drops to 40psi at around 110f or so. Oil is still pretty thick at that temperature and before this changeover is reached im usually still idling at 80psi+. I'd like to see that threshold changed to like 140f+ before dropping pressure target to basically what it is during a hot idle.

the setpoints are based on rpm*oil temp

seems 40psi at 110f ish is about right comparing to my table

the setpoints are based on rpm*oil temp

seems 40psi at 110f ish is about right comparing to my table

Yeah oil temp is what I meant. Just rattling numbers off as it's something I have passively observed while sitting at traffic lights on a cold start. Once oil gets to that temp the pressure seems to bypass and drop but in reality the oil is still really thick and not flowing well yet. Probably done for economy reasons. Just a thought that it might not be the best condition for bearing life if you then go to pull out onto the highway or away from a light aggressively while the car is targeting the same oil pressure as when the oil is at 200f.

Yeah oil temp is what I meant. Just rattling numbers off as it's something I have passively observed while sitting at traffic lights on a cold start. Once oil gets to that temp the pressure seems to bypass and drop but in reality the oil is still really thick and not flowing well yet. Probably done for economy reasons. Just a thought that it might not be the best condition for bearing life if you then go to pull out onto the highway or away from a light aggressively while the car is targeting the same oil pressure as when the oil is at 200f.

agreed...which is exactly why playing around with these tables maybe beneficial...

but i dont have an external oil temp + pressure gauge to tell if changing the values makes any difference

agreed...which is exactly why playing around with these tables maybe beneficial...

but i dont have an external oil temp + pressure gauge to tell if changing the values makes any difference

Oh I see that's an N54 bin? I thought map controlled oil pressure would only be relevant to N55.

Oh I see that's an N54 bin? I thought map controlled oil pressure would only be relevant to N55.

yea its n54...good question...havent really thought about it lol

does it have an electronic valve of sorts? if not then i guess the only use would be for adjusting when it complains about low oil pressures

yea its n54...good question...havent really thought about it lol

does it have an electronic valve of sorts? if not then i guess the only use would be for adjusting when it complains about low oil pressures

I've only seen N54 and previous generations of BMW's oil pressure sensor being referred to as a "switch," as in, the only thing it can do is complete a circuit when x pressure condition is met (<7psi). Not scaleable. But, I could be wrong.

Yes, the N55 has a valve/solenoid (almost like a VANOS solenoid) that sits in the main oil galley. I was under the impression that the map controlled oiling was done with this valve, but, again I could be wrong. Seems like the N55 engine pdf infers that the map controlled characteristic oiling is done via the oil pump itself. I think that is a misleading statement though.

I was under the impression that the valve worked as a sort of bypass that allows excess pressure to return to the pan when duty cycle is applied to it but maybe it is more complex than how I was thinking about it. Both N54 and N55 use a "sliding vane" style oil pump capable of variable output. Neither plugs into anything though so not sure how it could be map controlled outside of an indirect relationship to something like the oil control valve that the N55 has.Oil pump uses a Duroplast slide valve and it is electronically controlled based on a characteristic map within the engine management.

Maybe it works in opposite fashion where this valve restricts oil flow thus raising pressure. The oil pump reacts by moving less volume of oil to get pressure back in check?

The electrohydraulic pressure control valve controls the pump output and is bolted to the front of the engine block. It is operated based on a characteristic map within the DME (ECM) which in turn is based on feedback from the oil pressure sensor. The N55 uses a special oil pressure sensor for this purpose which functions in the similar way as the HPI fuel pressure sensor.

Last edited:

This new development could be interesting. I'm surprised there's an oil pressure table for the N54. Maybe it's a calculated oil pressure somehow? Who knows.

Also @Asbjorn I will likely be doing something similar to my oil pan in the future. Might just get the VAC baffle but also put in a secondary oil scavenge pump that pulls it from the front like you did and have it wired to a switch. I found one thats 3.7 gph and uses -8an lines, it should work perfect. Maybe I'll try and find a away to put the hole in the bottom/front slightly towards the side that's prone to pooling since that's where the main issue lies.

Also @Asbjorn I will likely be doing something similar to my oil pan in the future. Might just get the VAC baffle but also put in a secondary oil scavenge pump that pulls it from the front like you did and have it wired to a switch. I found one thats 3.7 gph and uses -8an lines, it should work perfect. Maybe I'll try and find a away to put the hole in the bottom/front slightly towards the side that's prone to pooling since that's where the main issue lies.

This new development could be interesting. I'm surprised there's an oil pressure table for the N54. Maybe it's a calculated oil pressure somehow? Who knows.

Also @Asbjorn I will likely be doing something similar to my oil pan in the future. Might just get the VAC baffle but also put in a secondary oil scavenge pump that pulls it from the front like you did and have it wired to a switch. I found one thats 3.7 gph and uses -8an lines, it should work perfect. Maybe I'll try and find a away to put the hole in the bottom/front slightly towards the side that's prone to pooling since that's where the main issue lies.

3.7gpm / 8an sounds somewhat similar to what I'm using. How many watts does it consume? I'm afraid you will experience the same problem I am, ie that it cant keep up, because it flows less than 20% of the engine. And it wont be picking up any oil unless you are braking.

If you do go for this, try to install the outlet at the front passenger side of the sump, as low as possible, and the inlet at the rear drivers side, inside the baffle.

I removed the oil pressure sensor on my car, and replaced it with an adjustable oil pressure switch, connected to a loud siren, mounted inside the cabin. So for future trackdays, I wont be logging or watching the exact oil pressure. Instead I will get an audible warning if oil pressure falls below 60psi or so, and otherwise live in happy ignorance.

Next week we will start replacing the rod bearings and look into installing a dip stick as well as enlarging the oil sump. It seems it can only be enlarged towards the gearbox, and I would happy if we can add a liter or so. In my logic, it should help to have extra volume behind the pickup, as the oil starvation mainly happens when turning after trail braking. No idea if Im right about this.

Similar threads

- Replies

- 1

- Views

- 848

- Replies

- 1

- Views

- 327