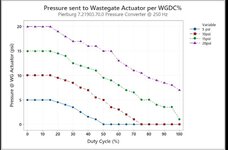

I'm trying to figure out what the capabilities are of the PS750 for the N55E PWG. I notice a a tune where I'm targeting 28#, in 4th gear at 6000 RPM at 94.4% WGDC boost starts tapering down from 28# ending up at 24.4# at 6750 RPM at the same WGDC, and I know a flat WGDC will cause boost to decrease but it's already at ~95%. In a tune where I had 100% WGDC from ~5750 RPM on, boost still started dropping at 6250 RPM. Does anyone know how much boost this turbo should be capable of for this platform?

I have tested everything to make sure nothing is not functioning correctly as listed below.

Boost leak test: pumped up 35# on the inlet of the turbo and only slowly leaked pressure after releasing the air hose.

Pure HDWGA: Used a MityVac on the line going to the WGA, cranked up 20 inhg and over the course of about 22 minutes lost ~2 inhg, so not bad.

Valve cover: Used a MityVac connected to the port feeding the boost solenoid, cranked up 20

inhg and over the course of 20 minutes lost 0 inhg.

Boost solenoid: Used a MityVac in the VAC inlet port, cranked up 20 inhg and lost about 1.5 inhg over the course of about 20 minutes.

Tested that the WGA was actually going to full close: Made a CWG tune with the CWG table at 100 for the entire table. Flashed and idled the car, MHD showed 100 WGDC, I got under the car and marked the shaft right at the WGA housing. Shut the car off, connected the MityVac to the WGA line again, cranked up 20 inhg and the shaft was in the same position as when the car was running using its own vacuum.

I have another Pure HDWGA on a shelf in the garage that I'll swap out to verify I'm getting the full range of motion on that.

I have tested everything to make sure nothing is not functioning correctly as listed below.

Boost leak test: pumped up 35# on the inlet of the turbo and only slowly leaked pressure after releasing the air hose.

Pure HDWGA: Used a MityVac on the line going to the WGA, cranked up 20 inhg and over the course of about 22 minutes lost ~2 inhg, so not bad.

Valve cover: Used a MityVac connected to the port feeding the boost solenoid, cranked up 20

inhg and over the course of 20 minutes lost 0 inhg.

Boost solenoid: Used a MityVac in the VAC inlet port, cranked up 20 inhg and lost about 1.5 inhg over the course of about 20 minutes.

Tested that the WGA was actually going to full close: Made a CWG tune with the CWG table at 100 for the entire table. Flashed and idled the car, MHD showed 100 WGDC, I got under the car and marked the shaft right at the WGA housing. Shut the car off, connected the MityVac to the WGA line again, cranked up 20 inhg and the shaft was in the same position as when the car was running using its own vacuum.

I have another Pure HDWGA on a shelf in the garage that I'll swap out to verify I'm getting the full range of motion on that.