DIY DIY EKPM3 Active Cooling for LPFP

- Thread starter fmorelli

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The fan looks nice.

Are there holes for the hot air to escape? I saw more of your posts on another forum that show the added heat sinks but if the air can't blow into the case and escape somewhere then I don't see how the air will flow and cool things.

I agree with ajm8127 The bottom aluminum is really the heat sink here. Adding the small one on the top side chip isn't likely to do much when there is a 50x bigger one already on case bottom.

Has anyone tried a fan that blows air thorough a finned heatsink added to the outside of the case like ajm8127 but also with a fan? That would likely be much more effective.

The the more metal the air flows through the better it will cool.

-Rich

Last edited:

Yes, there are a bunch of holes drilled in the side for the hot air to escape.The fan looks nice.

Are there holes for the hot air to escape? I saw more of your posts on another forum that show the added heat sinks but if the air can't blow into the case and escape somewhere then I don't see how the air will flow and cool things.

I agree with ajm8127 The bottom aluminum is really the heat sink here. Adding the small one on the top side chip isn't likely to do much when there is a 50x bigger one already on case bottom.

Has anyone tried a fan that blows air thorough a finned heatsink added to the outside of the case like ajm8127 but also with a fan? That would likely be much more effective.

The the more metal the air flows through the better it will cool.

-Rich

I have a Walbro 535 and Walbro 450 on this setup and ran some races last year, no issues at all.

Just wanted to say Thx for this thread. Gave me the confidence to put the thermal tape layers on and use thermal adhesive to put a heat sink on the mosfet. I also stuck some old finned heat sinks I had lying around to the back of the mount. Coded with Protool and we are running. Will have to see if the 6393 code comes back...(crosses fingers)

Just wanted to say Thx for this thread. Gave me the confidence to put the thermal tape layers on and use thermal adhesive to put a heat sink on the mosfet. I also stuck some old finned heat sinks I had lying around to the back of the mount. Coded with Protool and we are running. Will have to see if the 6393 code comes back...(crosses fingers)

So far so good. No codes, car is running fine.

FWIW, my stock EKP3 (top) versus the $40.00 brand new Ebay one. Working fine so far on a PR 2.5 with a 535 pump. My original lasted 120,000 miles with a stage 2 PR running on it for the past 50,000 miles. The pic of the chip is the OEM.

Attachments

What type of board is that mounted too? Any pics of it with the EKP cover off?

Do you mean the Fan? I 3D printed the board the fan is mounted on. I don't know if I have any pics with the cover off as it has been a while.What type of board is that mounted too? Any pics of it with the EKP cover off?

Ah, okay. Thanks.Do you mean the Fan? I 3D printed the board the fan is mounted on. I don't know if I have any pics with the cover off as it has been a while.

I've been thinking about this 'problem' for a little while.

I'm not going to go back and read but I'm fairly confident I know why they overheat. Our low pressure sensor is at the HPFP line. That's (guestimated) 20 feet from the fuel pump. That is around 28psi of pressure drop. Or the pressure at the pump output line is actually 70psi + 28psi (or whatever the pressure drop is). Look up on the fuel pump chart how many amps 98psi is (and flow to also understand why you need 2 pumps at such a low power level). I believe it's right on that 20 Amp line, which I believe the EPDM is rated for.

But then there's the Filter/Regulator that is rumored to be set below that, IIRC. So the target really can't be held and is only really reached when the HPFP demand isn't at peak ... once you grab 4th pressure crashes.

It all comes back to line size and pressure drop because of. Fans and the like, aren't going to fix the root problem.

I'm not going to go back and read but I'm fairly confident I know why they overheat. Our low pressure sensor is at the HPFP line. That's (guestimated) 20 feet from the fuel pump. That is around 28psi of pressure drop. Or the pressure at the pump output line is actually 70psi + 28psi (or whatever the pressure drop is). Look up on the fuel pump chart how many amps 98psi is (and flow to also understand why you need 2 pumps at such a low power level). I believe it's right on that 20 Amp line, which I believe the EPDM is rated for.

But then there's the Filter/Regulator that is rumored to be set below that, IIRC. So the target really can't be held and is only really reached when the HPFP demand isn't at peak ... once you grab 4th pressure crashes.

It all comes back to line size and pressure drop because of. Fans and the like, aren't going to fix the root problem.

i just installed my upgraded line. I believe the sensor is no more than 10ft from the pump including the in tank lines.I've been thinking about this 'problem' for a little while.

I'm not going to go back and read but I'm fairly confident I know why they overheat. Our low pressure sensor is at the HPFP line. That's (guestimated) 20 feet from the fuel pump. That is around 28psi of pressure drop. Or the pressure at the pump output line is actually 70psi + 28psi (or whatever the pressure drop is). Look up on the fuel pump chart how many amps 98psi is (and flow to also understand why you need 2 pumps at such a low power level). I believe it's right on that 20 Amp line, which I believe the EPDM is rated for.

But then there's the Filter/Regulator that is rumored to be set below that, IIRC. So the target really can't be held and is only really reached when the HPFP demand isn't at peak ... once you grab 4th pressure crashes.

It all comes back to line size and pressure drop because of. Fans and the like, aren't going to fix the root problem.

Attached another / my solution:

I drilled holes in the holder bracket, added some longer screws (still a little bit short) and used thermal paste between the heatsink / EKPM3. (Besides this I exchanged the thermal pad in the module and added a mini heatsink on the motor bridge with thermal glue as already mentioned here).

The big heatsink dimension is 100mm x 100mm x 18mm. Clearance is not a problem. I did nothing with the cables behind the heatsink (not necessary, see pics). Car: E90

I drilled holes in the holder bracket, added some longer screws (still a little bit short) and used thermal paste between the heatsink / EKPM3. (Besides this I exchanged the thermal pad in the module and added a mini heatsink on the motor bridge with thermal glue as already mentioned here).

The big heatsink dimension is 100mm x 100mm x 18mm. Clearance is not a problem. I did nothing with the cables behind the heatsink (not necessary, see pics). Car: E90

Attachments

Last edited:

Old thread but I like where this was going and found it very useful.

I am looking to have a dual Walbro 450 pump setup and am not a big fan of the Hobbs switch setup that most people run.

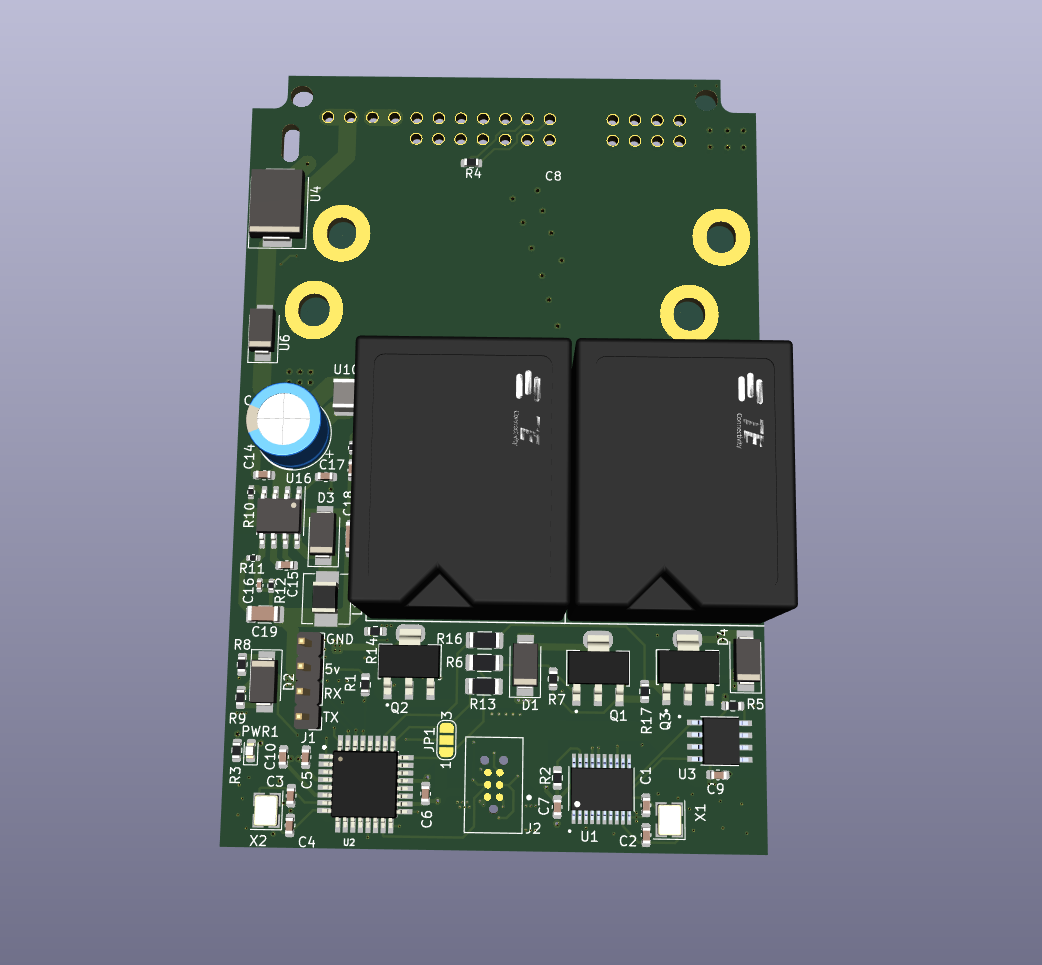

As second hand EKPM modules are relatively cheap on eBay, my plan is to modify two with the BTN8982 motor drivers and the high performance thermal pads discussed in this forum and run one for each pump.

Additionally, I have polished the aluminum surface the thermal pad contacts as well as the back of the EKPM module with some fine grit sandpaper.

As I don't want two EKPMs on the CAN bus confusing the DME, I will be running only one on the CAN bus while the second one will simply mirror the output of the first. I realize this is overkill but why not . Step one in making this happen has been to probe my HW 04 EKPM and put together some schematics so that I can see what is going on. As there are newer revisions of the EKMP and there are clones on eBay I hope this is ok to post.

. Step one in making this happen has been to probe my HW 04 EKPM and put together some schematics so that I can see what is going on. As there are newer revisions of the EKMP and there are clones on eBay I hope this is ok to post.

I will post photos of my setup as I go.

I am looking to have a dual Walbro 450 pump setup and am not a big fan of the Hobbs switch setup that most people run.

As second hand EKPM modules are relatively cheap on eBay, my plan is to modify two with the BTN8982 motor drivers and the high performance thermal pads discussed in this forum and run one for each pump.

Additionally, I have polished the aluminum surface the thermal pad contacts as well as the back of the EKPM module with some fine grit sandpaper.

As I don't want two EKPMs on the CAN bus confusing the DME, I will be running only one on the CAN bus while the second one will simply mirror the output of the first. I realize this is overkill but why not

I will post photos of my setup as I go.

Attachments

Isn't there an aftermarket unit that will talk with the DME and now run two pumps?Old thread but I like where this was going and found it very useful.

EKPM Upgrade Board

Features Supports all E series engines including 335i(N54/N55), 335D Supports F series N55 PWG/EWG. (EWG support in beta) Upgradable firmware and configuration through OBD2 with K+D Can cable Crash detection emergency fuel shutoff Directly controls two fuel pumps Switched grounded output for...

speedsty.com

Yes, but that unit uses a relay to turn each pump either full on or full off. That is not how the BMW engineers wanted the system to work  .

.

I am sure it works fine in reality but you end up with either both pumps working at 100% when they don't need to or probably around a 1 second delay between the control unit turning the second pump on and it providing the requested fuel.

What I want is the system to work as designed where the DME can request a flow rate and I will have two pumps provide that flow rate. As I believe it uses closed loop control, it should be able to dial in the correct amount and adjust smoothly. At least that is the plan.

Also a second hand v4 EKPM module is much cheaper .

.

I am sure it works fine in reality but you end up with either both pumps working at 100% when they don't need to or probably around a 1 second delay between the control unit turning the second pump on and it providing the requested fuel.

What I want is the system to work as designed where the DME can request a flow rate and I will have two pumps provide that flow rate. As I believe it uses closed loop control, it should be able to dial in the correct amount and adjust smoothly. At least that is the plan.

Also a second hand v4 EKPM module is much cheaper

Similar threads

- Replies

- 1

- Views

- 583