"Hi,

I’m working on an ‘07 N54 engine that I’m refreshing. When setting up the camshaft timing, I used the old bolt to verify everything was in time. I carefully checked the camshaft threads and the bolt, and both were undamaged. The old bolt torqued to spec (20 Nm + 180°) without any issues.

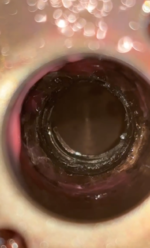

However, when I replaced it with a new bolt, the threads inside the camshaft stripped after only about 50°. I’m not sure why this happened.

I went to a BMW dealership and spoke to a master technician, but they only work on N55 engines. They recommended cleaning the threads, applying thread locker, and tightening the bolt until it bottoms out, but I’m not confident in that solution.

Should I try a helicoil repair, or would it be better to replace the camshafts? I’m worried this might happen with the new camshafts too.

How can I prevent this issue?

Any advice would be greatly appreciated!"

I’m working on an ‘07 N54 engine that I’m refreshing. When setting up the camshaft timing, I used the old bolt to verify everything was in time. I carefully checked the camshaft threads and the bolt, and both were undamaged. The old bolt torqued to spec (20 Nm + 180°) without any issues.

However, when I replaced it with a new bolt, the threads inside the camshaft stripped after only about 50°. I’m not sure why this happened.

I went to a BMW dealership and spoke to a master technician, but they only work on N55 engines. They recommended cleaning the threads, applying thread locker, and tightening the bolt until it bottoms out, but I’m not confident in that solution.

Should I try a helicoil repair, or would it be better to replace the camshafts? I’m worried this might happen with the new camshafts too.

How can I prevent this issue?

Any advice would be greatly appreciated!"